Φ 273 Accu-Roll Mill

273 unit main equipment adopts the domestic leading new Diesel rolling tube unit, which has the advantages of high rolling precision, wide specification range, uniform wall thickness, excellent internal and external surface quality, advanced technology, and adopts concentrated roll deformation and core rod pre-preparation. Rotating and other leading processes, and equipped with a high level of online heat treatment facilities and special tube finishing lines to ensure the stability of product quality.

Φ 159 PQF CONTINUOUS

The Φ 159 unit is the most advanced three-roller mandrel continuous rolling equipment in the world. It is equipped with a high-level heat treatment and pipe processing production line for deep processing of pipe products.

Φ 89 PQF CONTINUOUS

Φ 89 seamless steel tube continuous rolling mill is the first professional production line of O32mm-(D114mm small diameter continuous rolling seamless steel pipe in China.This project is the world’s first six-stand three-roll continuous rolling mill for small-diameter seamless steel pipe production. A high level ofautomation control and intelligent manufacturing, selected as China’s steel technology innovation global NO.1.

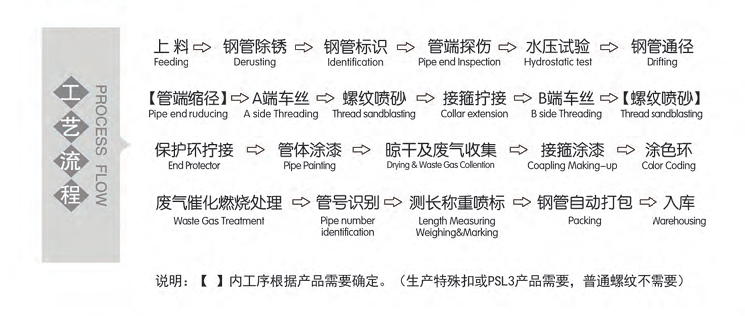

Φ 180 CASING & TUBING PROCESSING MILL

The Φ180 casing and tubing processing line has an annual output of 120,000 tons,with processing range as Φ60.3~Φ177.8mm, wall thickness 4.42~22.22mm, The product is mainly used for oil and gas extracting.

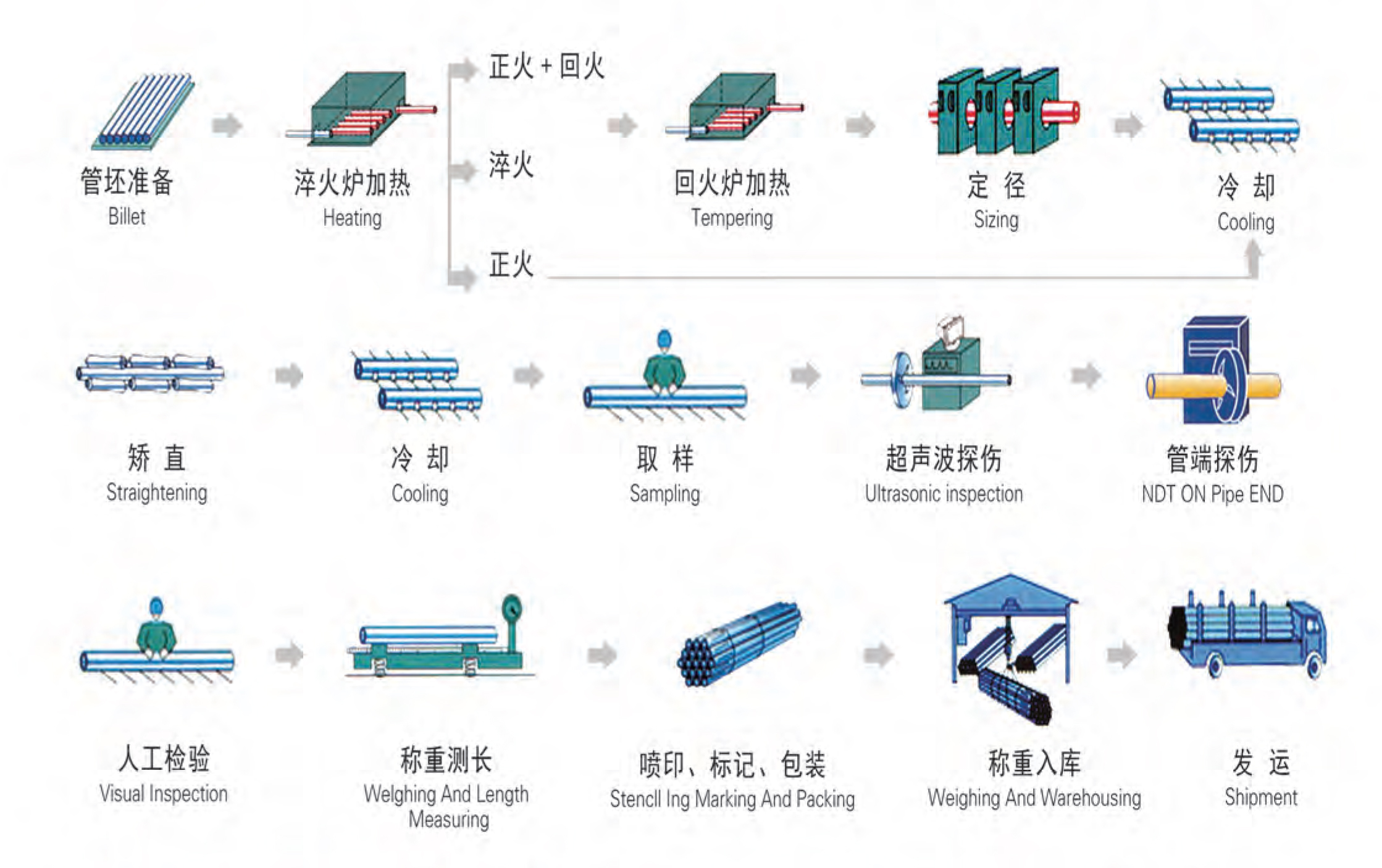

HEAT TREATMENT

With a heat treatment capacity of 150,000 tons, it integrates the most advanced dip-quenching + axial heat treatment technology and non-destructive testing technology to meet the requirements of heat treatment process for different steel grades. The product covers a wide range and the performance after heat treatment is stable.